Manufacturing Facilities

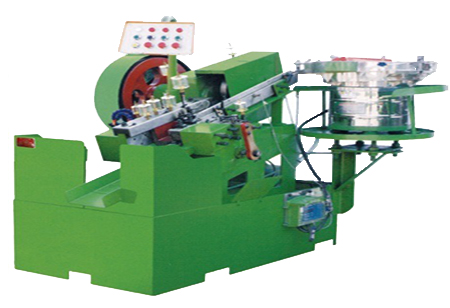

The company uses the Cold Forging methodology to manufacture precise and close-tolerance industrial fasteners. Cold heading machines enable the manufacture of industrial fasteners of the most complex and critical dimensions/nature with ease, speed and reliability. Also a variety of product range in terms of length, diameter and other related dimensions can be manufactured on these machines

The manufacturing equipment at our facility accommodates versatility and allows the plant to operate self sufficiently.

Manufacturing Scope

| MACHINE | CAPACITY | NOS. |

|---|---|---|

| M12 Multi Station Header | M12 X 85 | 03 |

| M12 Single Station Header | M12X100 | 01 |

| M8 Multi Station Header | M8X75 | 01 |

| M6 Multi Station Header | M6X50 | 02 |

| M6 Single Station Header | M6X50 | 04 |

| M12 Thread Rolling Machine | M12X100 | 02 |

| M6/M5 Thread Rolling Machine | M6X50 | 04 |

| M3 Thread Rolling Machine | M3X25 | 02 |

| M12 Trimming Machine | M12X100 | 02 |

| M6 Trimming Machine | M6X50 | 01 |

| M5 Washer Assembly Machine | M5X40 | 02 |

| BT Slotting Machine | M4X20 | 01 |

Cold Forging Technology:

Our machines ranges from a variety of single station to multi station headers which are capable of forging components from diameters of 2mm upto 14mm with the desired accuracy and precision which is the need of the industry today.

Thread Rolling:

Thread rolling is another important factor for a component and we have the machines capable for thread rolling and knurling parts from 2mm to 14mm

Washer Assembly Machine:

To add to the product varieties, we also have inhouse washer assembly machines to assemble washers from M3-M6 range. Washer assembly includes spring washer assembly or plain washer assembly or both.

BT Slotting Machine:

This machine is capable of making slots on the shank of screws and rivets in the range of M2-M5.

Apart from the above, the company also has support equipments such as lathes, surface grinder, lapping machine, muffle furnace, hardness tester, profile projector etc to support manufacturing and tooling related activities.Chat With Us